Roll-up fire gates EI-60 Firerollgate

Completed works

Roll-up fire gates and window curtains

Roll-up fire gates and window curtains  Rolled fire doors for IKEA warehouse

Rolled fire doors for IKEA warehouse  Roll-up fire-fighting gates EI60 for Megi

Roll-up fire-fighting gates EI60 for Megi The principle of operation of fire-resistant roller gates

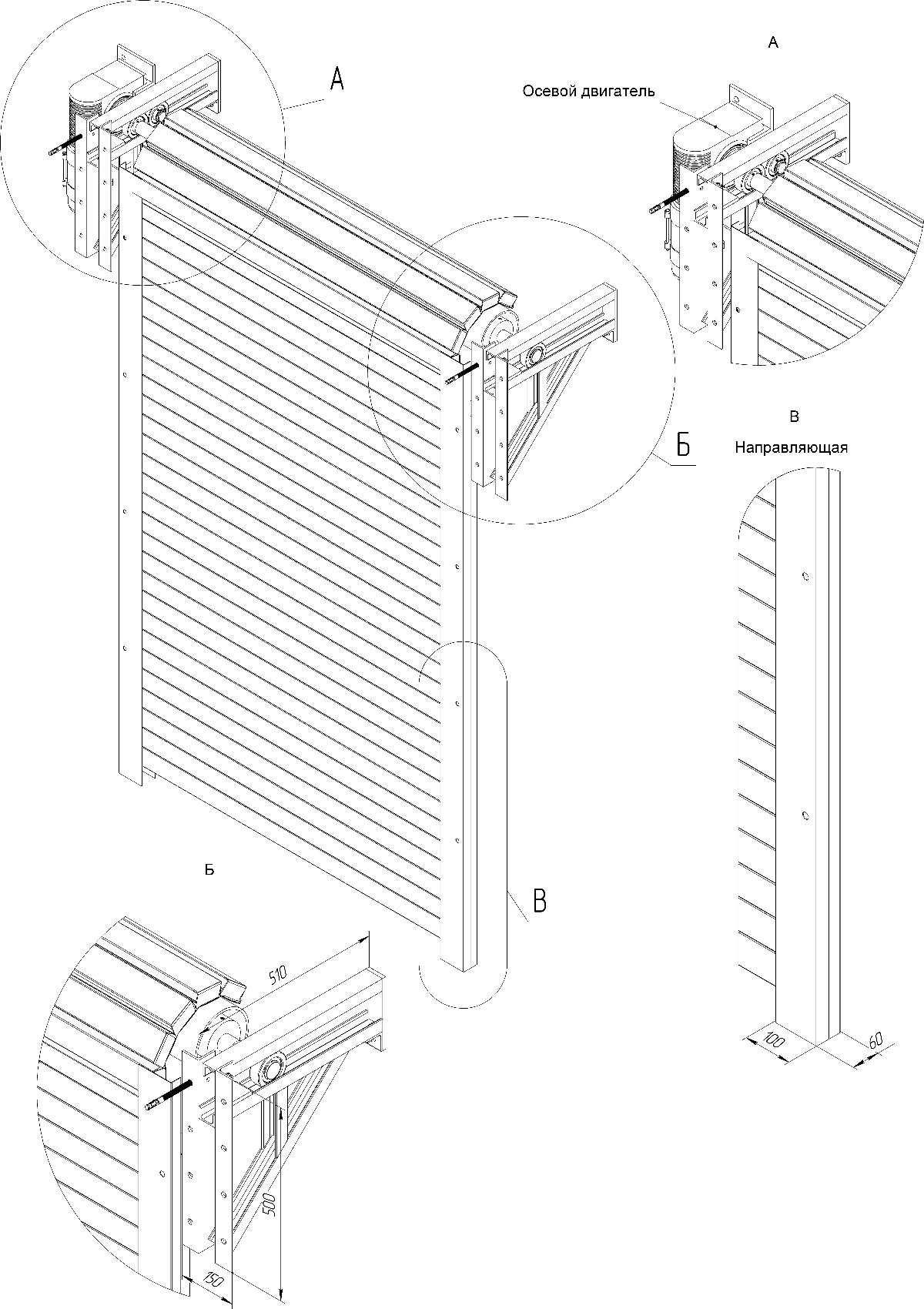

Lowering of the canvas is carried out only by means of an electric motor. The final positions of the web are fixed by limit switches. The electric motor is controlled through the control unit, the signal comes to the "dry contact" from the fire alarm. In case of power outages, emergency power supply is possible via a UPS with a battery.

For large gate sizes, a 380 V drive is used.

The canvas of the gate fire barrier:

1. A variant with a filler made of mineral fillerIt is made of movably interconnected sections of 0.5 mm thick sheet steel with a mineral wool filler with a density of 100 kg/m3;

Canvas weight: 25 kg/m2;

Thickness: 50 mm;

Height of one section: 80 mm;

Color version: any color on the RAL color scale or galvanized steel.

2. Option with a filler made of expanded mineral filler

It is made of movably interconnected sections of 0.7 mm thick sheet steel with a filler made of a thermal expansion element enclosed between two layers of flame retardant fabric;

Canvas weight: 13 kg/m2;

Thickness: 15 mm;

Height of one section: 80 mm;

Color version: any color on the RAL color scale or galvanized steel.

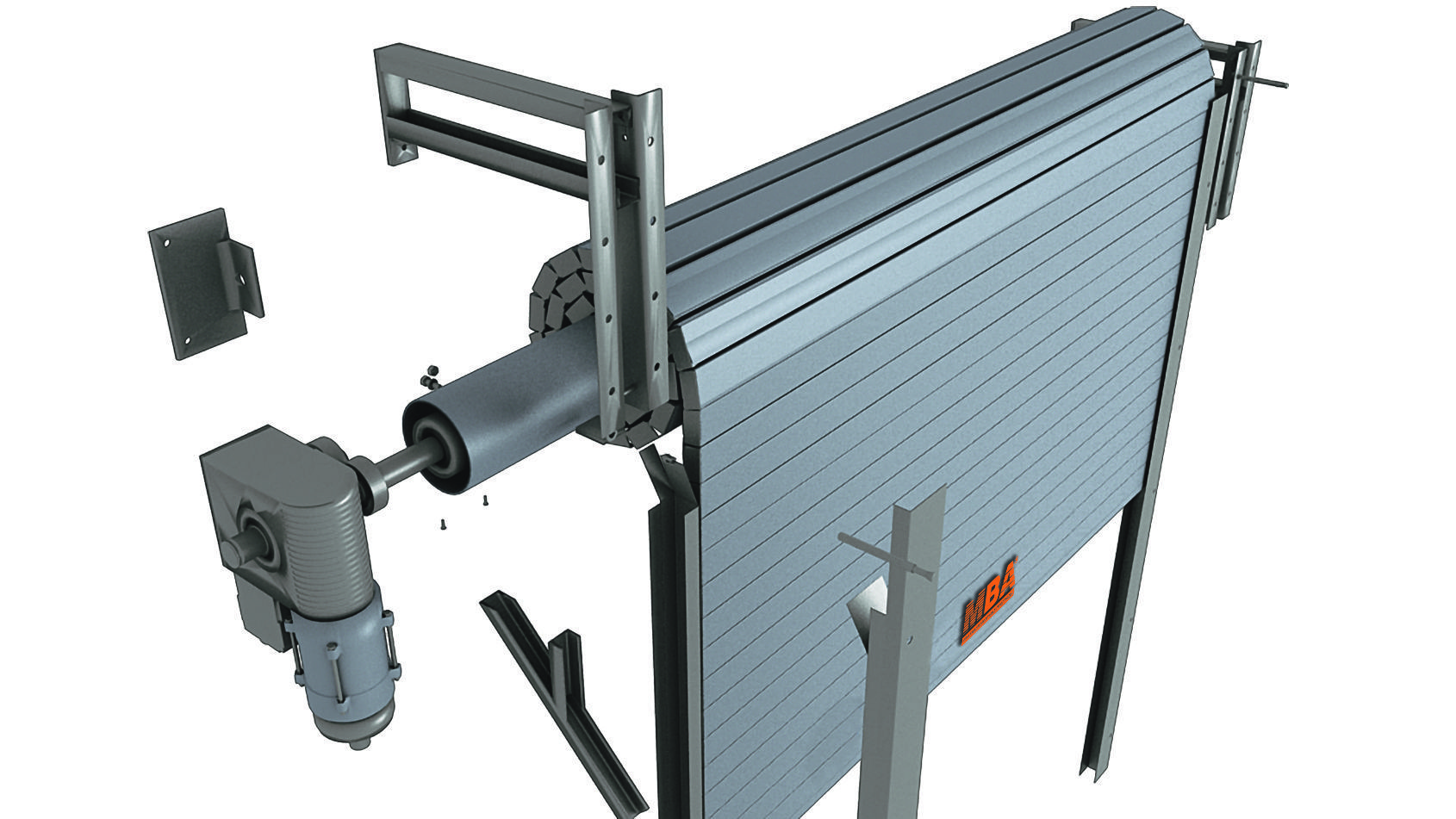

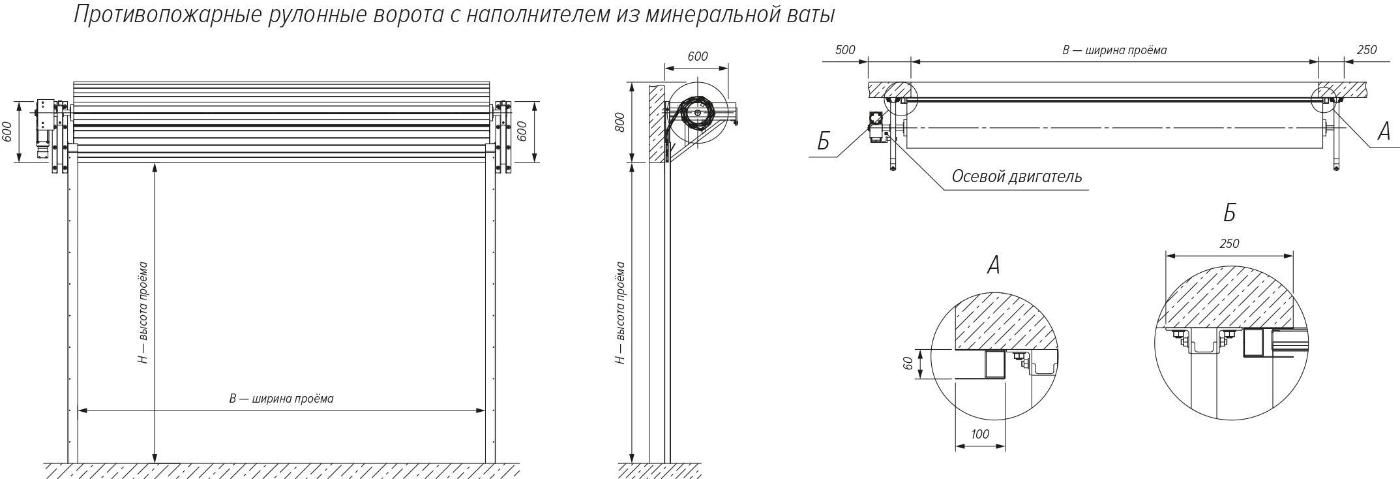

Side guides

They are made of a U-shaped profile made of steel with a thickness of 2 mm and a size of 100x60 mm. Color version: any color on the RAL color scale or galvanized steel.

Roll gate mounting options

The required place in the upper part of the opening for the installation of the gate:

-

with mineral wool filler: at least 800 mm;

-

with a filler made of expanded mineral filler: at least 600 mm.

The required place on the side of the electric drive installation: at least 500 mm.

Required space on the side adjacent to the electric drive: at least 250 mm.

Dimensions

| Products | Width, max. | Height, max. |

| Gates with mineral wool | 8+ m. | 5+ m. |

| Gates with a swollen mineral filler | 8+ m. | 6+ m. |

We can make fire-fighting gates according to individual sizes, check with the manager

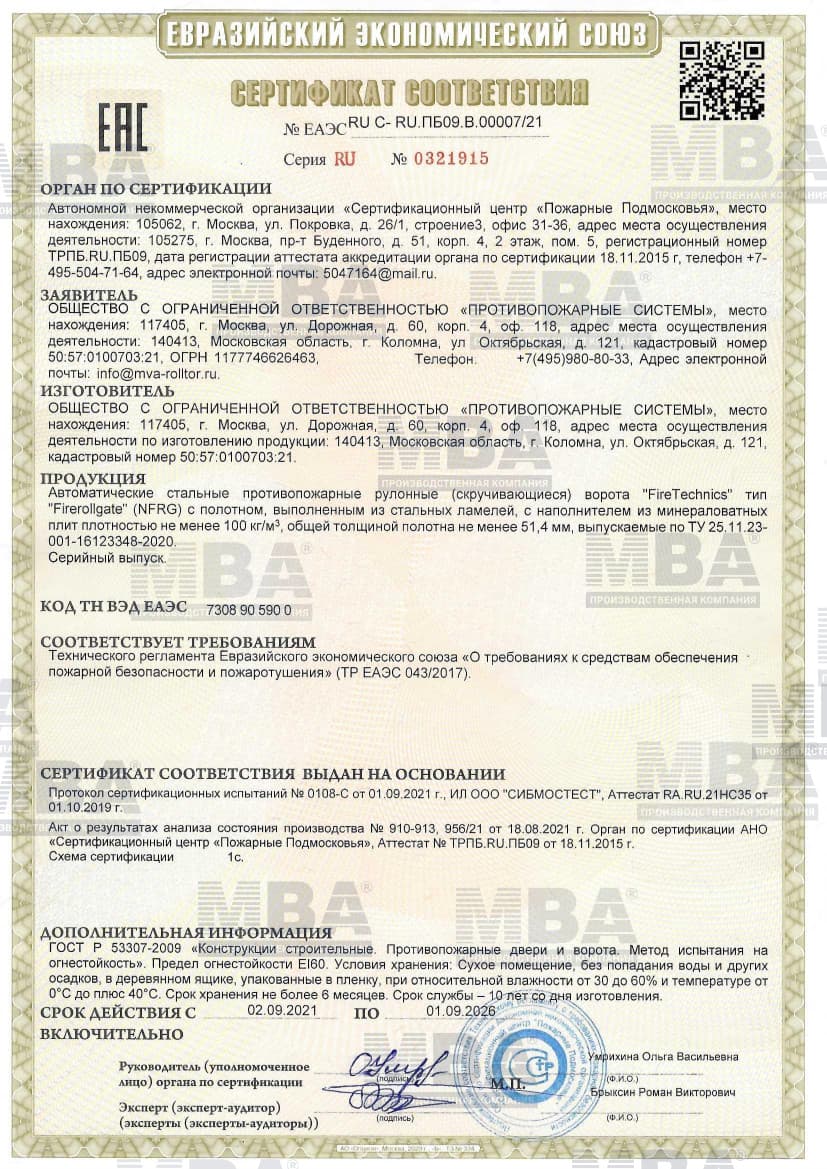

The main advantage and feature of such a locking structure is its compactness. In its folded state, the rolled fire gates are folded into a roll wound on a shaft raised to the ceiling. To ensure the ease of opening and closing the opening, the design is provided with folding consoles and "floating" bearings, which ensure reliable closure and eliminate the distortion of the web.

A thermoactive seal is installed around the perimeter, which expands when heated. It is designed to exclude the possibility of smoke and gas penetration through closed roll fire gates.

Such locking systems are ideal for installation in crowded places, industrial and commercial facilities with an increased risk of fire, as well as hazardous industries. The advantages of such models of fire-resistant structures include:

- Increased degree of fire resistance. Based on the structural features, sufficient fire safety of the building can be ensured with the help of a gate with a fire resistance of 60 minutes. During such a time, the canvas of the fire-resistant roller gates will not let fire and volatile gorenje products through;

- Production of non-combustible roll gates according to the norms of domestic GOST standards and taking into account international fire safety requirements;

- Autonomy, which makes it possible to integrate into almost any fire-fighting system. The ability to be equipped with autonomous power sources gives them the ability to function even in an emergency situation with a power outage;

- Compact dimensions - automatic twisting fire doors do not take up much space inside and outside the room, since the canvas moves vertically;

- Ease of installation, which reduces the cost of roll-up fire-resistant gates. They can be mounted only from the outside of the openings;

- The products are constantly checked and tested, which is confirmed by certificates of conformity.

- The web - (when filled internally with mineral wool) is made of movably connected sections based on half-millimeter thick sheet steel filled with mineral wool with a density of about 100 kg / metr3. Such a canvas weighs 25 kg running meter, and its thickness is 50 mm. The colors of the exterior finish can be any, according to the RAL table.

- If we are talking about the use of a filler made of a swollen material, then a special thermally expanding composition is the basis of a movable steel web made of a 0.7 mm thick material. Such barriers are easier to obtain – their canvas weighs only 13 kg / meter 2, and the thickness is 1.5 cm.

- The side guides are made of a steel U-shaped profile with a thickness of 2 mm and a width of slightly more than 10 centimeters.